Copp Abv

Copp Abv, formally known as Copper Alcohol By Volume, refers to the alcohol concentration achieved in distilled spirits, particularly when copper equipment is utilized in the distillation process. This article explores the significance of copper in distillation and its influence on the final alcohol content.

Key Takeaways

- Copp Abv (Copper Alcohol By Volume) is a term denoting the alcohol concentration in spirits produced using copper stills.

- Copper stills do not chemically alter the alcohol percentage but significantly enhance the spirit’s purity and flavor.

- The interaction between copper and the distillate removes undesirable sulfur compounds, leading to a cleaner, smoother product.

- Improved purity from copper distillation can result in a more consistent and often higher effective ABV for the desired alcohol fraction.

- Understanding copper’s role is crucial for distillers aiming for high-quality spirits with specific alcohol content profiles.

What is Copp Abv (Copper Alcohol By Volume)?

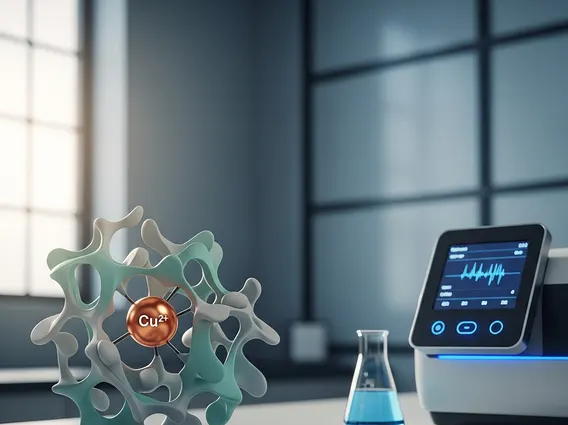

Copp Abv, or Copper Alcohol By Volume, is a specialized term referring to the percentage of ethanol present in a distilled spirit that has been processed using copper stills. While “alcohol by volume” (ABV) is a universal measure of alcohol concentration, the prefix “Copp” highlights the integral role of copper in achieving the spirit’s final characteristics, including its purity and, by extension, its effective alcohol content. The copper still abv meaning extends beyond a mere numerical value; it encompasses the qualitative impact of copper on the distillate, which indirectly influences how the alcohol content is perceived and experienced.

In essence, ABV measures the volume of pure ethanol as a percentage of the total volume of the solution at 20°C (68°F). For instance, a spirit labeled 40% ABV contains 40 milliliters of pure ethanol for every 100 milliliters of the spirit. When discussing Copp Abv, the focus shifts to how the material of the still—copper—contributes to the integrity and consistency of this measurement by refining the spirit during its production. This refinement process ensures that the measured ABV represents a cleaner, more desirable ethanol fraction, free from many common impurities.

How Does Copper Influence Alcohol By Volume in Distillation?

The question of how does copper affect alcohol by volume in distillation is primarily answered by understanding copper’s unique chemical properties as a catalyst and purifier. Copper does not directly increase or decrease the percentage of alcohol by volume through a chemical reaction with ethanol. Instead, its influence is more nuanced, focusing on the removal of undesirable compounds that would otherwise dilute the quality and alter the sensory profile of the spirit. This purification process leads to a distillate where the measured ABV is more representative of pure, desirable ethanol.

During distillation, the alcohol vapor interacts with the copper surfaces of the still. Copper reacts with sulfur compounds, such as dimethyl trisulfide, which are naturally produced during fermentation and can impart off-flavors and aromas (e.g., rotten eggs, burnt rubber) to the spirit. By binding with these sulfur compounds, copper effectively removes them from the vapor stream. This catalytic action results in a cleaner, smoother, and more aromatic spirit. The enhanced purity means that a greater proportion of the final volume consists of ethanol and desirable flavor compounds, leading to a higher quality product where the what is abv in copper distillation measurement truly reflects a superior spirit.

The copper still alcohol content explanation further elaborates on this. While the physical separation of alcohol from water and other congeners occurs due to differences in boiling points, copper’s role ensures that the separated alcohol fraction is of higher purity. This purity can lead to a more consistent and often higher effective ABV for the desired spirit fraction because fewer impurities are carried over. Distillers often choose copper stills for their ability to produce spirits with a refined character, where the alcohol content is not just a number but an indicator of a well-crafted product.

Key ways copper influences the distillate’s quality and effective ABV include:

- Sulfur Compound Removal: Copper reacts with and removes volatile sulfur compounds, preventing off-notes and ensuring a cleaner taste profile.

- Flavor Enhancement: By eliminating impurities, copper allows the desirable aromatic compounds to shine, contributing to a richer and more complex flavor.

- Improved Purity: The catalytic action of copper results in a purer distillate, which means the measured ABV corresponds to a higher concentration of ethanol free from undesirable elements.

- Consistent Quality: Copper stills help maintain a consistent quality across batches, ensuring that the target ABV is achieved with a superior product every time.