Pipe

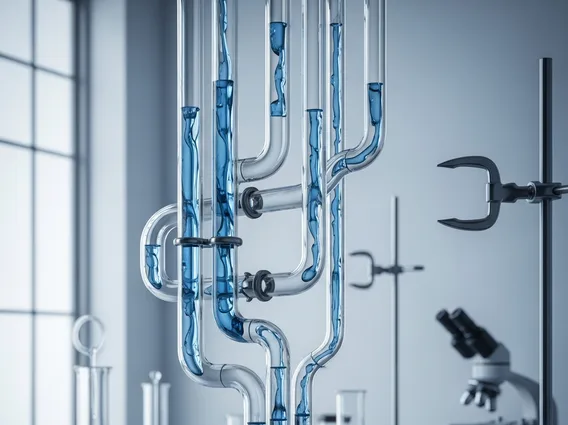

In medicine, a Pipe refers to a broad category of tubular structures or conduits, essential for the transport of fluids, gases, or even cells within the body or as part of medical interventions. These structures are critical for maintaining physiological functions and facilitating various diagnostic and therapeutic procedures.

Key Takeaways

- In a medical context, a Pipe is a tubular structure, either anatomical (like blood vessels) or a man-made medical device (like catheters or stents).

- Medical pipes are crucial for functions such as fluid transport, drainage, and providing access for diagnostic and therapeutic procedures.

- Common materials used for medical pipes include biocompatible polymers (e.g., silicone, polyurethane) and metals (e.g., stainless steel, nitinol).

- The manufacturing of medical pipes involves specialized processes like extrusion and molding, ensuring precision, sterility, and functional integrity.

What is a Pipe? Definition and Function

In a clinical context, a Pipe is a general term encompassing any tubular conduit designed for the passage of substances within or outside the body. These can be naturally occurring biological structures, such as blood vessels or ducts, or engineered medical devices like catheters, drains, and shunts. Their primary function is to facilitate the controlled movement of liquids (e.g., blood, urine, cerebrospinal fluid), gases (e.g., oxygen), or even solid particles (e.g., medication delivery systems), playing a vital role in diagnosis, treatment, and patient support.

Types of Medical Pipes and Their Uses

Medical pipes come in various forms, each designed for specific clinical applications. These devices are engineered to interact safely and effectively with biological systems.

- Catheters: Flexible tubes inserted into body cavities, ducts, or vessels to drain fluids, administer fluids, or access surgical sites. Examples include urinary catheters, intravenous (IV) catheters, and central venous catheters, which are indispensable for fluid management and medication delivery.

- Stents: Small mesh tubes inserted into anatomical conduits, such as arteries, veins, or ducts, to keep them open, particularly after blockages or narrowing. They are crucial in cardiology to maintain blood flow and prevent restenosis.

- Drains: Tubes placed in the body to remove pus, blood, or other fluids from a wound or surgical site, preventing accumulation and promoting healing. Post-operative drains are common after various surgical procedures.

- Shunts: Medical devices that divert fluid from one area of the body to another. They are commonly used to relieve pressure from cerebrospinal fluid buildup in hydrocephalus or to create vascular access for dialysis.

Common Pipe Materials and Their Applications

The selection of common pipe materials explained for medical applications is critical, as these materials must be biocompatible, durable, and capable of withstanding rigorous sterilization processes. The choice of material directly impacts the device’s performance, safety, and suitability for short-term or long-term implantation.

Polymers such as silicone, polyurethane, and polyethylene are frequently used due to their flexibility, inertness, and ability to be molded into various shapes. Silicone, for instance, is highly biocompatible and often preferred for long-term implants like shunts and feeding tubes due to its stability and resistance to degradation. Polyurethane offers a good balance of strength and flexibility, making it suitable for many types of catheters. Metals like stainless steel, nitinol (a nickel-titanium alloy), and cobalt-chromium alloys are common for rigid pipes or those requiring high strength, such as stents. Nitinol, known for its superelasticity and shape memory, is particularly valuable for self-expanding stents, allowing for minimally invasive insertion.

Pipe Manufacturing Processes

Understanding how are pipes manufactured in the medical field involves specialized techniques to ensure precision, sterility, and functional integrity. These processes are highly regulated to meet stringent quality and safety standards, such as those set by the FDA.

Extrusion is a primary method for creating continuous lengths of medical tubing. In this process, molten polymer is forced through a die, forming a tube with a precise diameter and wall thickness. This technique is crucial for producing catheters, IV lines, and various drainage tubes. Injection molding is another vital process, used for creating complex components, connectors, and specific shapes that cannot be achieved through extrusion, ensuring intricate designs and tight tolerances. For enhanced flexibility, kink resistance, or torqueability, some medical pipes, especially those used in interventional procedures, are reinforced with braided wires or coiled structures embedded within the polymer layers. After forming, medical pipes often undergo surface treatments to improve lubricity or incorporate drug-eluting properties. Finally, all medical pipes must be rigorously sterilized (e.g., using ethylene oxide, gamma irradiation, or autoclaving) to prevent infection, adhering to strict regulatory standards.